| Igama lePortduct | Defrost heater Element |

| Ukufuma kwi-Insulation Resistance State | ≥200MΩ |

| Emva kokuFumana koBubushushu boVavanyo lwe-Insulation Resistance | ≥30MΩ |

| Ukuvuza kweLizwe lokufuma kwangoku | ≤0.1mA |

| Umthwalo ongaphezulu | ≤3.5W/cm2 |

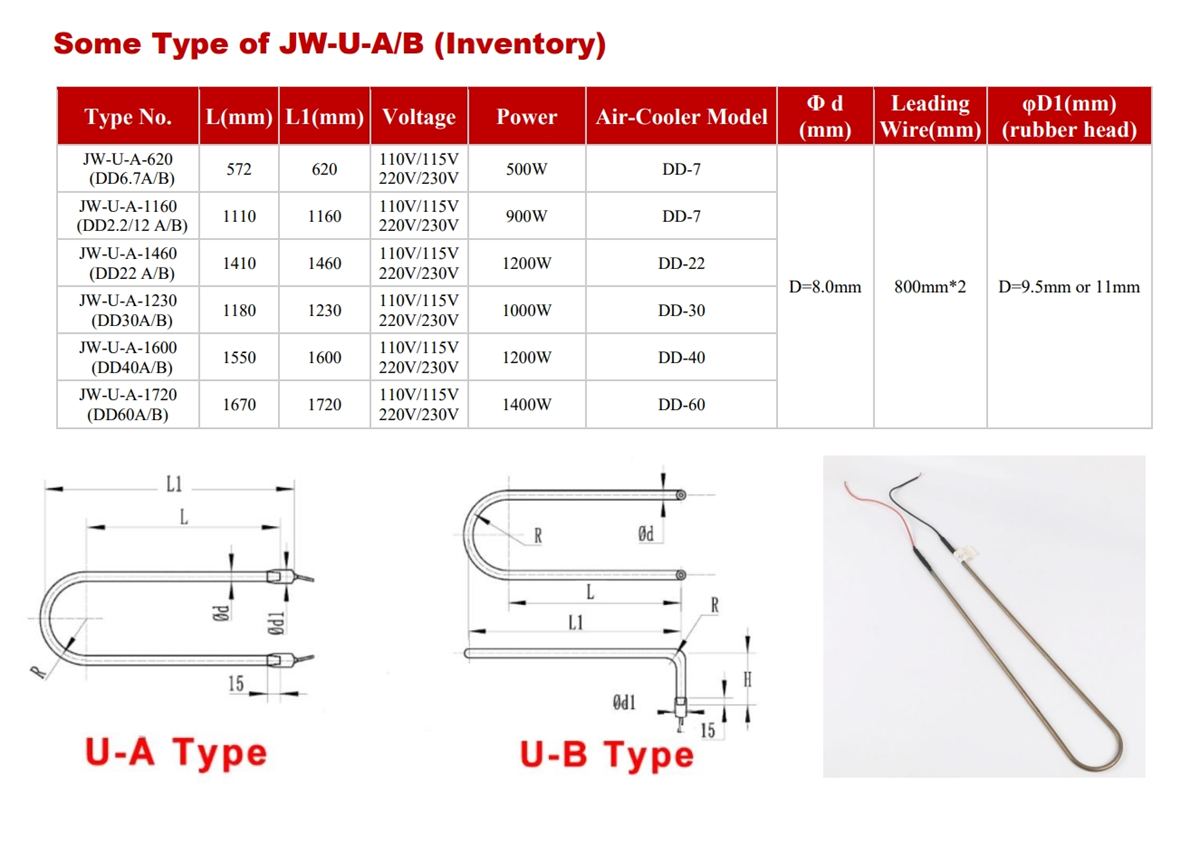

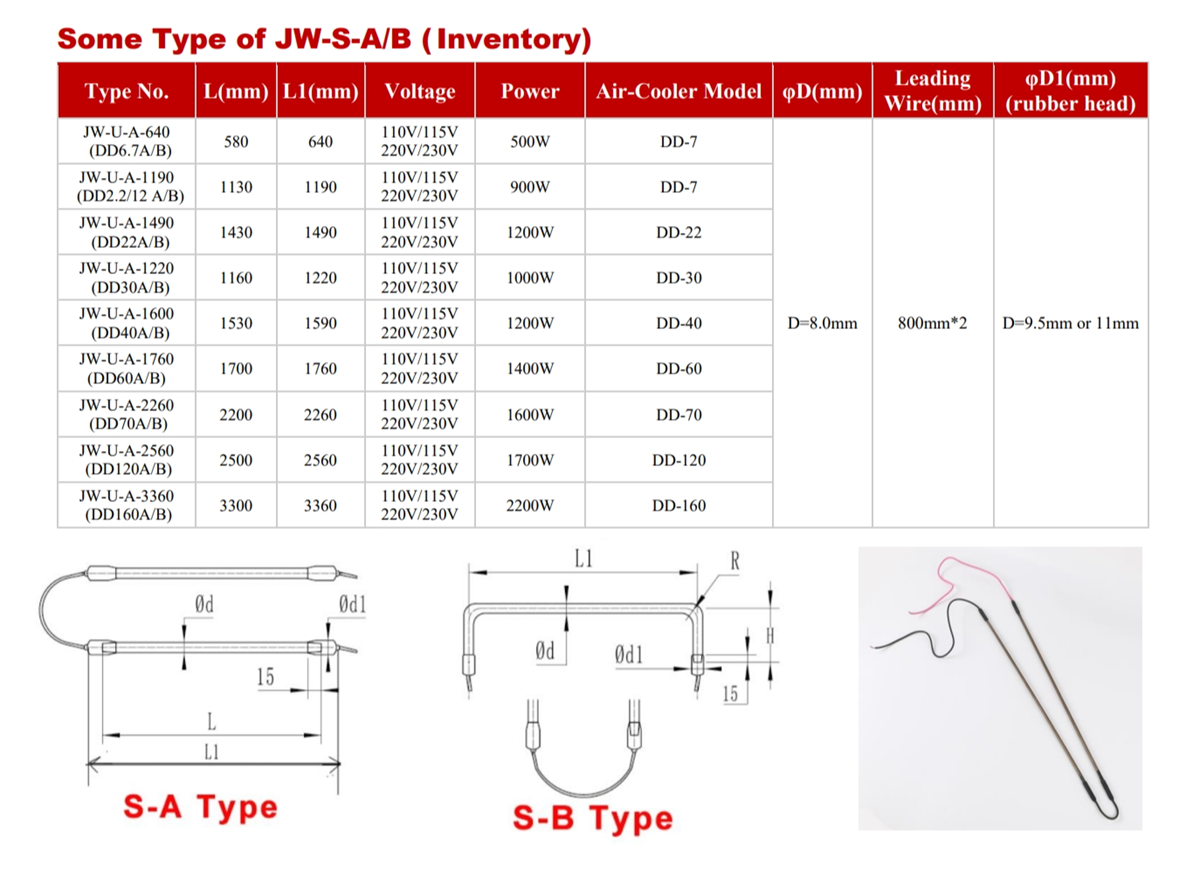

| Umbhobho ububanzi | 6.5mm, 8.0mm, 10.7mm, njl. |

| Ubume | ngqo, imilo ye-U, imilo ye-W, njl. |

| Umbane okwaziyo ukumelana namanzi | 2,000V/min (ubushushu bamanzi aqhelekileyo) |

| Ukumelana ne-insulated emanzini | 750MOhm |

| Sebenzisa | Defrost Heating Element |

| Ubude betyhubhu | 300-7500mm |

| Ubude bocingo lwelothe | 700-1000mm (ngokwesiko) |

| Iimvume | CE/CQC |

| Uhlobo lwetheminali | Customized |

| Idefrost isifudumezi elementimilo inetyhubhu enye ethe tye, ityhubhu ephindwe kabini ethe tye, imilo ye-U, imilo ye-W, kunye nayo nayiphi na enye imilo yesiqhelo. Inxalenye yesifudumezi-manzi epholileyo enocingo olukhokelayo itywinwe ngentloko yerabha, ingakhethwa ngokutywinwa ngetyhubhu eshwabeneyo. | |

Umgaqo wokufudumeza wedefrost isifudumezi elementkukusasaza intambo yokumelana nobushushu obuphezulu ngokulinganayo kumbhobho wensimbi engenasici ngobushushu obuphezulu, kwaye ugcwalise isithuba ngekristale ye-magnesium oxide engumgubo ene-conductivity entle ye-thermal kunye neempawu zokugquma. Esi sakhiwo asiqhubeki nje phambili, kodwa sinokusebenza kakuhle kwe-thermal, kunye nokufudumeza. Xa kukho ngoku kudlula intambo yokumelana nobushushu obuphezulu, Ubushushu obuveliswayo busasazwa kumphezulu wetyhubhu yesinyithi ngekristale ye-magnesium oxide powder, kwaye emva koko idluliselwe kwindawo eshushu okanye emoyeni, ukuze kufezekiswe injongo yokufudumeza. Ngokuba iqokobhe leisifudumezi-sisibethoyenziwe ngezinto zetsimbi, inokuxhathisa ukutshisa okomileyo, ukumelana nokugqwala kunye nokumelana nobushushu obuphezulu, kwaye iyakwazi ukuziqhelanisa neendawo ezininzi zokufudumeza. Kwayei-tubular defrost heaterinokwenziwa kwiimilo ezahlukeneyo, ukuhlangabezana neemfuno ezahlukeneyo zofakelo lwabathengi.

Defrost izifudumezizisetyenziswa ikakhulu kwizikhenkcisi nakwizixokelelwano zokukhenkceza ukuthintela ukwakheka kweqabaka nomkhenkce.

Idefrost ukufudumeza ityhubhuizicelo ziquka:

1. Ifriji: Faka iisifudumezi sokuqhaqhakwifriji ukunyibilikisa umkhenkce kunye neqabaka eqokelelwe kwikhoyili ye-evaporator, ukuqinisekisa ukusebenza kakuhle kwezixhobo kunye nokugcina ubushushu obuhambelanayo bokugcinwa kokutya.

2. Isikhenkcisi: Isebenzisa isikhenkcisidefrost heater ityhubhuukuthintela i-coil evaporator ekukhenkceni, ukwenzela ukuba ukuhamba komoya kube lula kwaye ukutya okufriziwe kugcinwe ngokufanelekileyo.

3. Iiyunithi zefriji yorhwebo:Izifudumezi zeTubular Defrostzibalulekile kwiiyunithi ezinkulu zefriji ezisetyenziswa kwiivenkile ezinkulu, iindawo zokutyela kunye nezinye iindawo zorhwebo ukugcina imfezeko yempahla etshabalalayo.

4. Inkqubo yokupholisa umoya: Kwiiyunithi zokupholisa umoya ezineentsimbi zokupholisa ezithanda ukwakheka kweqabaka,qhaqha izifudumezizisetyenziselwa ukunyibilikisa umkhenkce kunye nokuphucula ukusebenza kakuhle kokupholisa kwenkqubo.

5. Impompo yobushushu:Izifudumezi zokuqhaqhakwiimpompo zobushushu zinceda ukuthintela ukwakheka kweqabaka kwiikhoyili zangaphandle kwimozulu ebandayo, ukuqinisekisa ukusebenza kakuhle kwenkqubo kuzo zombini iindlela zokufudumeza kunye nokupholisa.

6. Ifriji yefriji: Amashishini afuna ifriji enkulu, njengokulungiswa kokutya kunye neendawo zokugcina, zisebenzisa izifudumezi ze-defrost ukugcina ukusebenza kakuhle kweenkqubo zabo zefriji kunye nokuqinisekisa umgangatho wemveliso.

7. Amagumbi abandayo kunye nezikhenkcezisi zokuhamba: iityhubhu zokufudumeza i-defrost zisetyenziswa kumagumbi abandayo kunye nezikhenkcezisi ezihambayo ukuthintela ukukhenkceza kwee-coil ze-evaporator kunye nokugcina ubushushu obuhambelanayo bokugcinwa kwezinto ezininzi ezinokonakala.

8. Iibhokisi zokubonisa ezifakwe efrijini: Amashishini afana negrosari kunye neevenkile ezithengisa lula zisebenzisa iikesi zokubonisa ezifakwe efrijini ezinezifudumezi zokuqhaqhazela ukubonisa iimveliso ezikhenkcezisiweyo ngaphandle komngcipheko wokubonakala kweqabaka.

9. Iilori ezifakwe efrijini kunye nezikhongozeli: izifudumezi zokuqhaqha zisetyenziselwa ukumisa iinkqubo zokuthutha efrijini ukuthintela ukwakheka komkhenkce kunye nokuqinisekisa ukuba iimpahla zigcinwa zikwimeko efanelekileyo ngexesha lokuthutha.

Phambi kombuzo, pls usithumelele ngezantsi iinkcukacha:

1. Usithumelela umzobo okanye umfanekiso wokwenyani;

2. Ubungakanani beheater, amandla kunye nombane;

3. Naziphi na iimfuno ezikhethekileyo zesifudumezi.

Abafowunelwa: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314