Idefrost heater ityhubhu yokufudumezalelona candelo libalulekileyo kwisixhobo sokukhenkceza. Umsebenzi oyintloko we-heater defrost kukususa umkhenkce kunye neqabaka eyenziwe ngaphakathi kwezixhobo zefriji ngenxa yendawo yokushisa ephantsi ngokufudumeza. Le nkqubo ayikwazi kuphela ukubuyisela ukusebenza kokupholisa kwezixhobo, kodwa nokukhusela ngokufanelekileyo izixhobo kumonakalo obangelwa ukuqokelela kweqhwa kunye neqhwa. Oku kulandelayo kuya kucacisa ngokweenkcukacha kwimiba emine: umsebenzi, umgaqo wokusebenza, ukusetyenziswa kwenkqubo yesikhenkcisi kunye nokubaluleka kwayoisifudumezi-sisibethoityhubhu yokufudumeza.

I. Umsebenzi weetyhubhu zokufudumeza isifudumezo se-Defrost

Ngethuba lokusebenza kwezixhobo zefriji, ngenxa yokushisa okuphantsi, umgca weqhwa kunye neqhwa lilungele ukwenza phezu kwezixhobo, ngokukodwa kwindawo ye-evaporator. Lo maleko weqabaka uya kuthintela ukuhamba komoya obandayo, unciphise ukusebenza kakuhle kokupholisa, kwaye usenokubangela umonakalo emzimbeni kwisixhobo. Ukusombulula le ngxaki, kwabakho imibhobho yokufudumeza i-defrost. Ikhupha ubushushu ukuze inyibilike ngokukhawuleza iqabaka phezu kobuso besixhobo, ngaloo ndlela ibuyisela umgangatho oqhelekileyo wokusebenza wezixhobo zefriji. Ngokomzekelo, kwifriji yasekhaya, ukuba iqabaka eninzi iqokelelana kwi-evaporator, iya kubangela ukuba ubushushu obungaphakathi kwendawo yesikhenkcisi bungakwazi ukufikelela kwixabiso elimiselweyo, okuchaphazela umphumo wokugcinwa kokutya. Ngeli xesha, iukufudumeza ityhubhu yokufudumezainokusebenza ngokukhawuleza ukuqinisekisa ukusebenza okuqhubekayo kunye nokusebenza kakuhle kwezixhobo.

Ii. UmGaqo wokuSebenzisa weMibhobho yokuFundisa i-Defrost

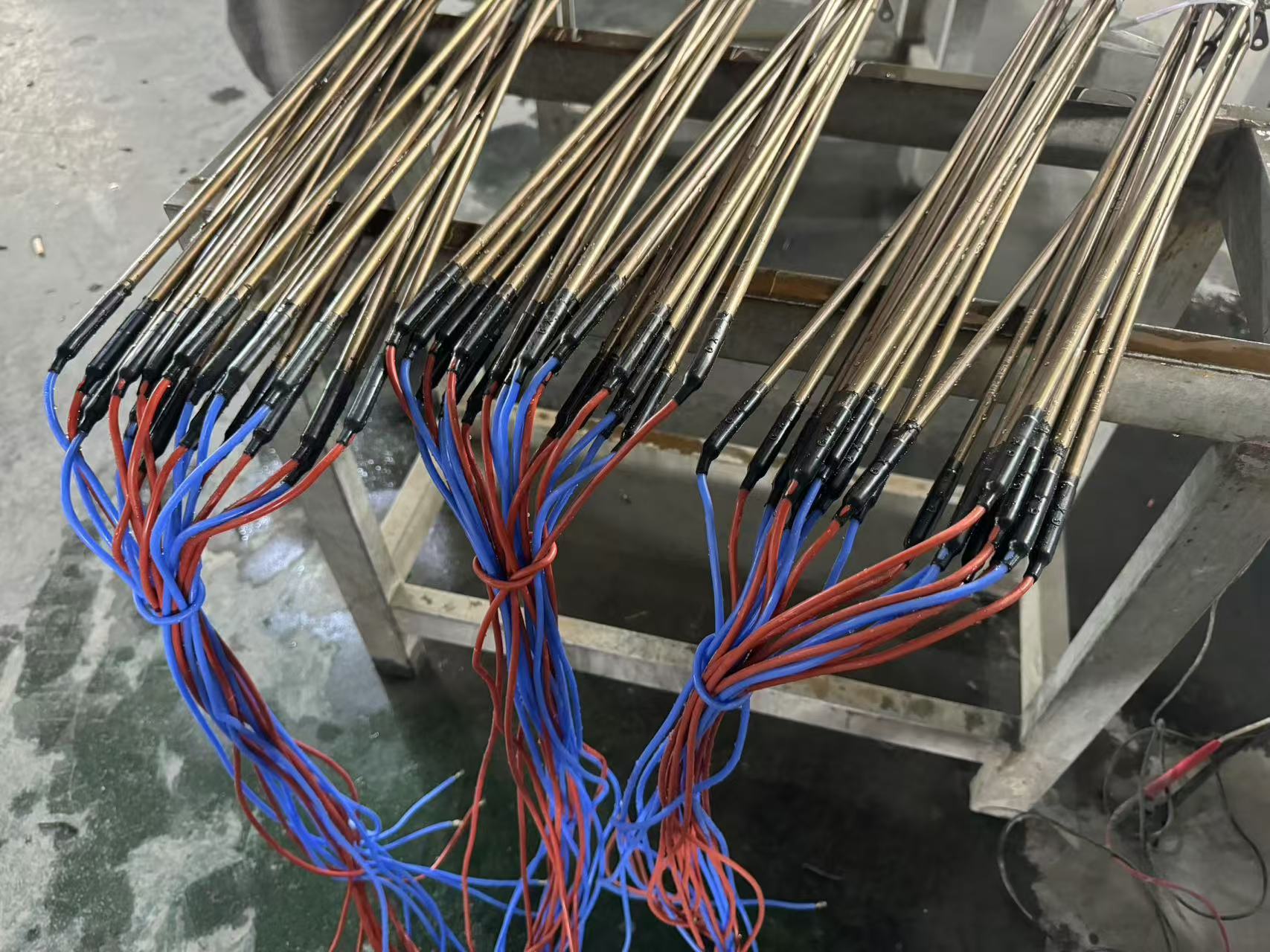

Umgaqo wokusebenza weityhubhu yokufudumeza isifudumeziisekwe kwitekhnoloji yokuguqula i-electrothermal. Icandelo layo eliphambili licingo lokufudumeza kombane, eliyinto ekwazi ukuguqula ngokufanelekileyo amandla ombane kumandla ombane. Xa izixhobo zefriji kufuneka ziqhube umsebenzi wokutshatyalaliswa, inkqubo yokulawula iya kuthumela umqondiso wokuqala kwi-tube yokushisa i-heater. Emva koko, umsinga wombane udlula kwintambo yokufudumeza, ubangela ukuba ufudumale ngokukhawuleza kwaye uvelise ubushushu. Obu bushushu budluliselwa kumphezulu wezixhobo, kubangela ukuba iqabaka inyibilike kancinci emanzini. Amanzi anyibilikisiweyo akhutshwa ngenkqubo yokuhambisa amanzi eyakhelwe-ngaphakathi yesixhobo sokuthintela ukuqokelelana ngaphakathi kwesixhobo, ngaloo ndlela igcinwe icocekile kwaye yomile.

Ukongeza, uyilo lwangokudefrost ukufudumeza iityhubhuikwajolise kugcino lwamandla kunye nokhuseleko. Ngokomzekelo, iimveliso ezininzi zisebenzisa i-ceramic insulating materials ukugubungela iingcingo zokufudumeza, ezingagcini nje ukunyusa umgangatho wokuqhuba ubushushu kodwa ziphucula ukhuseleko, ukukhusela umonakalo owenziwe ngengozi ngenxa yokushisa. Okwangoku, ezinye izixhobo eziphezulu zixhotyiswe ngeenzwa zokushisa, ezinokubeka iliso kwiqondo lokushisa elisebenzayo leetyhubhu zokufudumeza ngexesha langempela, ukuqinisekisa ukuba zisebenza ngaphakathi koluhlu olufanelekileyo kunye nokuphucula ngakumbi ukuthembeka kunye nobomi benkonzo yesixhobo.

Iii. Ukusetyenziswa kweMibhobho yokufudumeza i-Defrost kwiiNkqubo zeFriji

Iityhubhu zokufudumeza zisetyenziswa ngokubanzi kwizixhobo ezahlukeneyo zefriji, kubandakanywa kodwa kungaphelelanga kwiifriji zasekhaya, iifriji zorhwebo, i-air conditioners ephakathi, njl. Thatha iifriji zorhwebo njengomzekelo. Ngenxa yomthamo wazo omkhulu wogcino kunye nosetyenziso oluninzi, izinga apho iqabaka iqokelelana ngalo lihlala likhawuleza. Ngoko ke, kubaluleke kakhulu ukuba kuxhotyiswe ngeetyhubhu zokufudumeza ezisebenza kakuhle kakhulu, ezinokunciphisa kakhulu ingxaki yokunciphisa ukusebenza kwefriji okubangelwa ukuchithwa kwangaphambi kwexesha.

Ngokuqhubela phambili kwethekhnoloji, inani elikhulayo lezixhobo zefriji ziqalise ukwamkela iinkqubo zokulawula ezihlakaniphile ukulawula ukusebenza kweetyhubhu zokufudumeza. Ngokomzekelo, ezinye iifriji eziphakamileyo ziyakwazi ukugqiba ngokuzenzekelayo ukuba ziqalise inkqubo yokucima i-defrosting ngokusebenzisa i-humidity-in-humidity kunye nezinzwa zeqondo lokushisa, kwaye zilungelelanise ixesha lokusebenza kunye namandla eetyhubhu zokufudumeza ngokuhambelana neyona meko. Olu luyilo olukrelekrele aluphuculi kuphela isiphumo sokuqhaqha kodwa lunciphisa ngokufanelekileyo ukusetyenziswa kwamandla, ukubonelela abasebenzisi ngamava okusebenzisa alula kunye noqoqosho.

Iv. Ukubaluleka kokuTyalisa iMibhobho yokuFundisa

Iityhubhu zokufudumeza izifudumezi zidlala indima engenakuphinda ibuyiselwe kwaye ibalulekileyo ekusebenzeni okuqhelekileyo kwezixhobo zesikhenkcisi. Okokuqala, inokususa ngokufanelekileyo umkhenkce kunye neqabaka, iqinisekisa ukusebenza kakuhle kwefriji yezixhobo zefriji. Okwesibini, ngokususa rhoqo iqhwa kunye neqhwa, i-tube yokufudumeza i-defrosting inokwandisa ubomi benkonzo yezixhobo kunye nokunciphisa iindleko zokugcina. Ukuba isixhobo sokukhenkceza asinazo iityhubhu zokufudumeza okanye ukungasebenzi kakuhle kwazo, umkhenkce kunye neqabaka zinokuqokelelana ngokuqhubekayo, ekugqibeleni zibangele ukuba isixhobo singakwazi ukusebenza ngokuqhelekileyo. Ngokomzekelo, kwinkqubo yokupholisa umoya, ukuba iqabaka kwi-evaporator ayisuswanga kwangethuba, inokuvala indlela yomoya, ichaphazele ifuthe lokulawula ubushushu bangaphakathi, kwaye ibangele ukuba icompressor ilayishe kakhulu kwaye yonakale.

Ngoko ke, xa usebenzisa izixhobo zefriji kubomi bemihla ngemihla, abasebenzisi kufuneka bajonge rhoqo imeko yokusebenza kweetyhubhu zokufudumeza ukuze baqinisekise ukusebenza kwabo ngokuqhelekileyo. Ngokomzekelo, umntu unokugqiba enoba umbhobho wokufudumeza ukwimeko entle ngokuqwalasela enoba kukho nakuphi na ukufumba okungaqhelekanga komkhenkce neqabaka phezu kwesixhobo okanye ngokuphulaphula naziphi na izandi ezicacileyo zokufudumeza ebudeni benkqubo yokuqhaqha. Emva kokuba nayiphi na ingxaki ifunyenwe, amagcisa aqeqeshiweyo kufuneka aqhagamshelwe kwangethuba ukuze agcinwe ukuze kuthintelwe ukuchaphazela ukusebenza ngokubanzi kwezixhobo.

Isishwankathelo

Ukuqukumbela, ityhubhu yokufudumeza i-defrosting, njengenxalenye ephambili kwisixhobo sokukhenkceza, idlala indima ebalulekileyo. Ayinakususa kuphela umkhenkce kunye neqabaka ngokufudumeza ukuqinisekisa ukusebenza kakuhle kwefriji, kodwa ikhusela ngokufanelekileyo izixhobo kumonakalo obangelwa ngumkhenkce kunye neqabaka. Ngophuhliso oluqhubekayo lwetekhnoloji, iityhubhu zokufudumeza zexesha elizayo zilindeleke ukuba zamkele itekhnoloji ephucukileyo kunye nemathiriyeli, iphucula ngakumbi ukusebenza kwabo kakuhle kunye nokusebenza okonga amandla. Ngokomzekelo, ukusetyenziswa kwama-nanomaterials amatsha kunokunika i-tubes yokufudumeza i-defrosting kunye nokusebenza kakuhle kwe-thermal conduction, ngelixa ukuphuculwa kwenkqubo yokulawula ehlakaniphile kunokubavumela ukuba balungelelanise ngokuchanekileyo kwiimeko ezahlukeneyo zokusetyenziswa. Olu phuculo luya kubonelela abasebenzisi ngezisombululo ezisebenzayo nezithembekileyo zefriji, ezizisa ukukhululeka kunye nokuthuthuzela kubomi bemihla ngemihla.

Ixesha lokuposa: May-02-2025