Izinto ezifudumalayo zokufudumeza ziyinxalenye ephambili yeenkqubo zefriji, ngakumbi kwiifriji kunye neefriji.Umsebenzi wayo oyintloko kukuthintela ukuqokelelana komkhenkce kunye neqabaka kwisixhobo, ukuqinisekisa ukusebenza kakuhle kunye nolawulo lobushushu.Makhe sijonge ngakumbi indlela esi sifudumezileyo esisebenza ngayo.

Inkqubo yefriji isebenza ngokuhambisa ubushushu ukusuka ngaphakathi kwiyunithi ukuya kwindawo yangaphandle, ngaloo ndlela yenza ukushisa kwangaphakathi kuphantsi.Nangona kunjalo, ngexesha lokusebenza okuqhelekileyo, ukufuma emoyeni kuyajiya kwaye kukhenkce kwiikhoyili zokupholisa, ukwenza umkhenkce.Ngokuhamba kwexesha, lo mkhenkce unokunciphisa ukusebenza kakuhle kweefriji nezikhenkcezisi, nto leyo ethintela amandla azo okugcina ubushushu obungaguqukiyo.

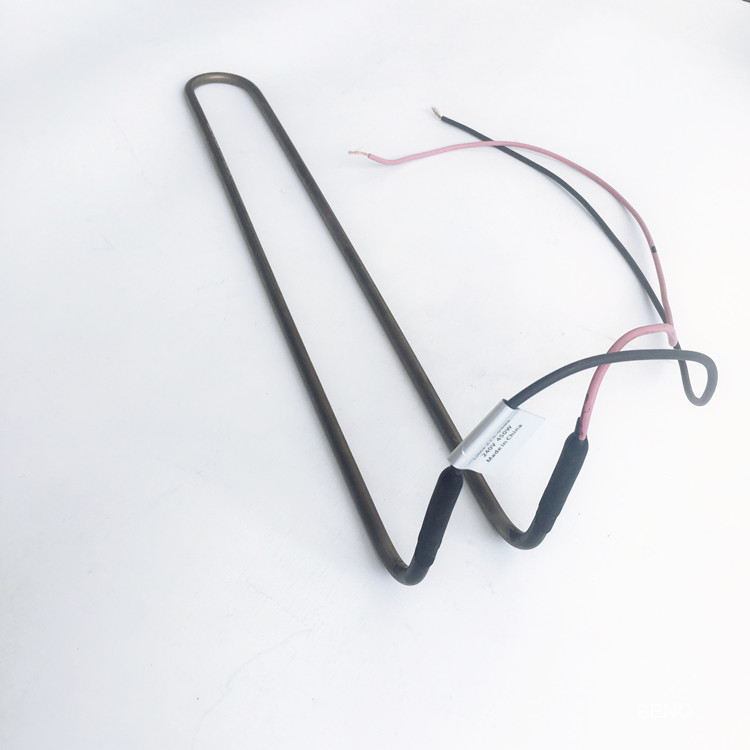

Isifudumezi setyhubhu ecolileyo sisombulula le ngxaki ngokufudumeza amaxesha ngamaxesha iikhoyili ze-evaporator eziqhele ukwenza umkhenkce.Oku kufudumeza kulawulwa kunyibilikisa umkhenkce oqokelelweyo, ukuwuvumela ukuba uphume njengamanzi kwaye uthintele ukufumba ngokugqithisileyo.

Izinto zokufudumeza zombane zokufudumeza enye yezona ntlobo zisetyenziswa ngokuqhelekileyo kwiinkqubo zefriji.Ziquka ucingo oluxhathisayo olutshisayo xa umsinga wombane udlula kuwo.Ezi zinto zibekwe ngobuchule kwikhoyili ye-evaporator.

Nje ukuba isebenze, umsinga uvelisa ubushushu, ukufudumeza iikhoyili kunye nokunyibilikisa umkhenkce.Wakuba uphelile umjikelo wokuphelisa iqabaka, ielementi iyayeka ukufudumeza kwaye ifriji okanye isikhenkcezisi sibuyela kwindlela yokupholisa eqhelekileyo.

Enye indlela esetyenziswa kwiinkqubo ezithile zokukhenkcisa kwimizi-mveliso kukuncitshiswa kwerhasi eshushu.Esikhundleni sokusebenzisa amacandelo ombane, iteknoloji isebenzisa ifriji ngokwayo, ixinzelelwe kwaye ishushu ngaphambi kokuba ikhokelwe kwi-coil evaporator.Irhasi eshushu itshisa ikhoyili, ibangela ukuba umkhenkce unyibilike kwaye ukhuphe ngaphandle.

Iifriji kunye neefriji zixhotyiswe ngenkqubo yokulawula ebeka esweni ubushushu kunye nomkhenkce.Xa inkqubo ibona ukuqokelelwa komkhenkce okubalulekileyo kwikhoyili ye-evaporator, ibangela umjikelo we-defrost.

Kwimeko ye-heater defrosting yombane, inkqubo yokulawula ithumela umqondiso ukuze kusebenze into yokufudumala.Into iqala ukuvelisa ubushushu, inyusa ubushushu bekhoyili ngaphezu komkhenkce.

Njengoko i-coil itshisa, umkhenkce ongaphezulu kwawo uqala ukunyibilika.Amanzi asuka kumkhenkce onyibilikayo aqukuqela kwitreyi yokuhambisa amanzi okanye ngenkqubo yokuhambisa amanzi eyenzelwe ukuqokelela nokususa amanzi kwiyunithi.

Emva kokuba inkqubo yokulawula igqibe ukuba umkhenkce owaneleyo unyibilikile, yenza ukuba i-defrosting element ingasebenzi.Inkqubo ke ibuyela kwimo yokupholisa eqhelekileyo kwaye umjikelo wokupholisa uyaqhubeka.

Izikhenkcezisi kunye nezikhenkcezisi zidla ngokwenza imijikelo yokususa ukhenkce ngokuzenzekelayo, ukuqinisekisa ukuba umkhenkce ugcinwa umncinci.Ezinye iiyunithi zikwabonelela ngeenketho zokususa ukhenkce ngesandla, ezivumela abasebenzisi ukuba baqalise imijikelo yokuqhaqha njengoko kufuneka.

Ukuqinisekisa ukuba isixokelelwano sokuhambisa amanzi sihlala singathintelwa sisitshixo sokunyibilikisa okusebenzayo.Iidreyini ezivalekileyo zinokukhokelela kumanzi amileyo kunye nokuvuza okunokwenzeka.Ukuhlolwa rhoqo kwe-element defrosting kubalulekile ukuqinisekisa umsebenzi wayo.Ukuba le elementi iyasilela, ukwakheka komkhenkce okugqithisileyo kunye nokuncipha kokupholisa kakuhle kunokubangela.

Izinto eziqhaqha ukhenkce zidlala indima ebalulekileyo ekugcineni ukusebenza kweenkqubo zesikhenkcisi ngokuthintela ukugcwala komkhenkce.Kungakhathaliseki ukuba ngokusebenzisa ukuchasana okanye iindlela zegesi eshushu, ezi zinto ziqinisekisa ukuba iikhoyili zokupholisa azinayo i-ice eninzi, evumela ukuba izixhobo zisebenze ngokufanelekileyo kwaye zigcine ubushushu obuphezulu.

Qhagamshelana: Amiee

Email: info@benoelectric.com

Umnxeba: +86 15268490327

Wechat /whatsApp: +86 15268490327

Isazisi seSkype: amiee19940314

Iwebhusayithi: www.jingweiheat.com

Ixesha lokuposa: Jan-25-2024